Stainless steel passivation

What is stainless steel passivation?

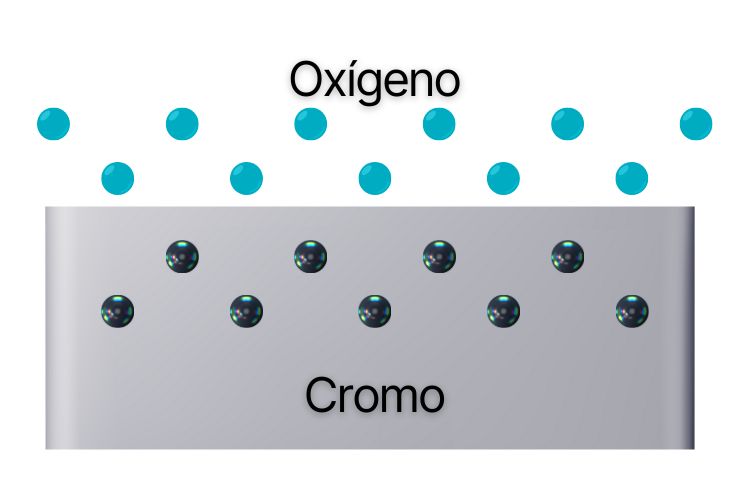

Stainless steel passivation is a key process to ensure corrosion resistance in demanding industrial environments. It is based on the formation of a thin but effective passive chromium oxide layer that acts as a protective barrier between the metal and its surroundings. This film forms naturally when the chromium present in the alloy reacts with oxygen in the air, creating a stable and uniform chemical defense.

This invisible layer is the main reason why stainless steel can withstand aggressive agents such as humidity, salinity, or chemicals. Without it, the steel would be exposed to oxidation and the progressive deterioration of its structure. That’s why understanding passivation is not just about a physicochemical phenomenon: it’s about knowing the secret behind the longevity and reliability of stainless steel in sectors such as food processing, pharmaceuticals, construction, or petrochemicals.

How does the passive layer work?

The passive layer of stainless steel is an extremely thin yet effective barrier that forms spontaneously when the chromium in the steel comes into contact with oxygen from the air or water. This layer is composed mainly of chromium oxide (Cr₂O₃) and serves to isolate the underlying metal from the environment, preventing reactions with corrosive agents.

Unlike other metallic materials that require external coatings or varnishes, stainless steel has the ability to naturally protect itself thanks to this passive layer. One of its most notable properties is its self-healing capability: if it is damaged mechanically or by chemical products, and the environment contains oxygen, the layer reforms on its own.

However, this regeneration is only possible if the steel surface is free of contaminants such as iron particles, oils, salts, or welding residues. If these remain, they can prevent the proper formation of the passive film or even promote localized corrosion.

For this reason, in many industrial applications it is recommended to clean the stainless steel surface with suitable abrasive products before carrying out the passivation treatment, ensuring that the protective layer forms uniformly and durably.

When is the passivation treatment applied?

Although stainless steel can naturally form a passive layer, there are situations where it is necessary to reinforce or restore this protection through a passivation treatment. This process is mainly applied after operations that alter or contaminate the steel’s surface, such as machining, welding, sanding, or handling with carbon steel tools.

These activities can introduce contaminants—such as free iron particles or metallic residues—that interfere with the natural regeneration of the passive layer and lead to the appearance of corrosion spots. In such cases, passivation acts as a deep-cleaning and reactivation stage for the steel.

The treatment is also highly recommended in sectors where stainless steel is exposed to especially aggressive conditions, such as salty environments, coastal areas, the food industry, or chemical facilities. In these contexts, a well-formed and stable passive layer is essential to ensure the material’s durability and hygiene.

There are several industrial passivation methods, but the most common use nitric acid or citric acid to dissolve free iron and promote the formation of chromium oxide. Both treatments must follow international standards such as those established by ASTM A967 or EN 2516 to ensure their effectiveness and safety.

Advantages of proper passivation

Passivation treatment for stainless steel not only restores its appearance and protects it from corrosion, but also offers a series of technical and economic benefits that justify its use, especially in demanding industrial environments.

Long-lasting corrosion protection

A well-formed passive layer acts as a continuous barrier against oxidizing agents, humidity, salty environments, or chemicals. This results in a longer service life for stainless steel structures or components.

Automatic regeneration of the protective layer

Unlike other treatments, stainless steel can spontaneously regenerate its passive layer in the presence of oxygen, as long as no contaminants are present. Passivation ensures that this regeneration occurs efficiently.

Improved hygiene and cleanliness

In sectors such as food or pharmaceutical, a clean, smooth, and passivated surface reduces the buildup of residues and microorganisms. This makes cleaning easier and meets sanitary standards.

Professional aesthetic appearance

Passivation removes heat tint, surface oxides, and contaminants, leaving a uniform, bright finish—ideal for visible or architectural applications.

Long-term savings

By reducing the need for maintenance, repairs, or replacements due to corrosion, passivation becomes a cost-effective investment. It enhances material performance and protects the value of the installation.

With all these advantages, it’s clear that stainless steel passivation is much more than a technical procedure: it is a key step to ensure durability, performance, and professionalism in any project.

Industrial applications of stainless steel passivation

Stainless steel passivation is an essential practice in multiple industrial sectors, where durability, chemical resistance, and hygiene are key factors. Below are some of the most common environments in which this treatment is indispensable:

1

2

3

4

5

Thanks to its adaptability and effectiveness, stainless steel passivation is a cross-functional solution that enhances performance and safety across a wide range of industries.

When and why should passivation be applied?

Passivation is not just an optional treatment but a strategic necessity in many industrial contexts. Although stainless steel naturally generates its passive layer when exposed to oxygen, there are situations where this protection is compromised and intervention is required.

After manufacturing or machining processes

Operations such as cutting, grinding, sandblasting, polishing, or welding can leave free iron residues or contaminant particles on the steel surface. These impurities interfere with the formation of the passive layer and can cause localized corrosion spots. Chemical passivation removes these residues and reactivates the surface, ensuring uniform protection.

In new installations or after repairs

Before commissioning stainless steel systems—such as tanks, pipelines, or machinery—it is advisable to carry out full passivation to ensure that the entire installation is free of contaminants and uniformly protected from the very beginning.

After aggressive cleaning or surface damage

Certain chemical products, abrasive cleanings, or physical impacts can damage or destroy the passive layer. In such cases, passivation helps restore the material’s protective integrity and prevent premature corrosion.

In especially aggressive environments

Marine, industrial, or high-chloride or acidic environments require additional protection. Passivation reinforces the stainless steel’s anticorrosive barrier, improving its resistance in extreme conditions.

To comply with regulations and audits

Many sectors—such as food, pharmaceutical, or chemical—require passivation as part of their quality and hygiene protocols. Applying it ensures compliance with international standards such as ASTM A967 or ISO 16048, while also providing traceability and reliability to the production process.

In short, passivation is a guarantee of quality, durability, and safety. Applying it at the right time prevents long-term problems and maximizes the return on investment of stainless steel.

Abrasive solutions for stainless steel maintenance

Stainless steel passivation is not just a chemical process but a guarantee of durability, resistance, and reliability. Its ability to protect against corrosion, regenerate in oxidizing environments, and adapt to extreme conditions makes it an essential solution in industrial, sanitary, food, and architectural sectors.

However, for the passive layer to perform its function effectively, it is essential to keep surfaces in optimal condition. This is where Abrasteel provides added value: we offer a wide range of abrasive products compatible with stainless steel, ideal for preparing surfaces without damaging them and ensuring effective passivation.

Our abrasive discs and brushes are designed to deliver precise performance, using non-contaminating materials and formats adapted to every need—from removing residues after machining to fine polishing before applying chemical treatments.

Looking for a professional solution for stainless steel maintenance and preparation?

At Abrasteel, you will find not only the most complete catalog of abrasive products, but also the technical guidance your company needs.

Fill out the contact form on our website, and one of our experts will get in touch with you shortly. We’re ready to help you enhance the durability of your projects!

Contact us

Leave us your details and one of our sales representatives will contact you shortly.