Abrasive brush: an essential tool for perfect finishes

The importance of abrasive brushes in the industry cannot be underestimated. These tools, often overlooked, play a crucial role in numerous manufacturing and maintenance operations. From removing unwanted material to precision polishing, abrasive brushes are used to improve the quality and efficiency of industrial processes. In this comprehensive guide, we will explore the world of abrasive brushes, highlighting how they become indispensable elements in the modern workshop.

What is an abrasive brush?

An abrasive brush is much more than a simple tool accessory; it is an innovative and essential solution in the field of industrial work. Each brush is meticulously designed with a series of bristles containing abrasive particles, integrated to perform specific tasks with remarkable efficiency and precision.

Diversity of materials

The bristles of an abrasive brush can be made from a variety of materials, allowing them to adapt to a wide range of applications:

Metal wires: These bristles are typically used in brushes for heavy-duty tasks, such as rust removal or cleaning metal surfaces. Their rigidity allows them to tackle hard and resistant materials.

Synthetic fibers: They offer a softer alternative, ideal for applications that require a delicate touch or a fine finish. These fibers are perfect for polishing or working on surfaces that cannot be damaged.

Composition and design

The composition of the bristles is only part of the story. The design of the brushes also plays a crucial role. Some brushes feature a dense and compact design for aggressive applications, while others have a more flexible and open arrangement, ideal for gentle cleaning tasks and even distribution of the abrasive material.

Flexibility and durability

The effectiveness of abrasive brushes lies in the combination of flexibility and durability. This duality allows the brush to adapt to surface irregularities while maintaining constant and effective pressure. This is essential for tasks that require precision, such as in the surface finishing industry or in maintenance applications where finish quality is paramount.

Versatile applications

Thanks to their innovative design and specialized materials, abrasive brushes can work on a variety of surfaces without losing their cutting or finishing capability. From deep cleaning of machinery parts to delicate polishing of electronic components, abrasive brushes are indispensable tools in the modern workshop.

Types of abrasive brushes at Abrasteel

Abrasteel recognizes the diversity of needs in the industry and therefore offers a wide range of abrasive brushes:

Shaft-mounted brushes

These brushes are ideal for detailed work in confined or hard-to-reach spaces. Their design allows for precise control, making them perfect for precision tasks.

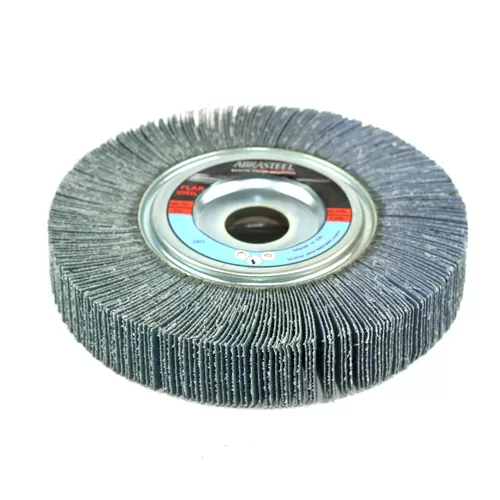

Core brushes

These brushes are designed to work on larger surfaces, providing a uniform and consistent finish. They are the ideal choice for jobs that require broader surface contact.

Brushes for satin finishing machines

Specifically designed for satin finishing machines, these brushes ensure an evenly satinized finish, ideal for surfaces that require an aesthetically pleasing appearance.

Ventilated brushes

With a design that allows better air circulation, these brushes are excellent for preventing overheating during prolonged work.

Felt brushes

These brushes are used for final finishing, especially on delicate metals where a gentle yet effective polish is required.

Uses of abrasive brushes with Abrasteel examples

Abrasteel’s abrasive brushes are versatile and essential tools across a wide range of industrial applications. Each type of brush is designed for a specific use, making them indispensable for different maintenance and finishing tasks. Below are some of their most common uses, along with examples of Abrasteel products:

Detailed cleaning and precision work

Abrasteel’s shaft-mounted brush, made of aluminum oxide cloth, is ideal for detailed cleaning in small or hard-to-reach areas. Its specific flexibility allows for precise work without damaging the underlying surface.

Grinding and finishing on large surfaces

For grinding and finishing tasks on larger surfaces, Abrasteel’s zirconium cloth core brush is exceptional. Its robust design makes it suitable for working on hard metals, delivering a uniform and efficient finish.

Fine finishing in jewelry and delicate metals

Abrasteel’s brushes for satin finishing machines, specifically designed for the jewelry industry, are perfect for polishing and achieving fine finishes on jewelry and other delicate metals, ensuring a smooth and elegant result.

Cleaning and polishing on large surfaces

Abrasteel’s ventilated brushes, made with non-woven fabric and aluminum oxide grain, are ideal for cleaning and polishing larger surfaces. Their ventilated design prevents overheating, ensuring continuous and efficient work.

Smooth and uniform finishing on metal surfaces

For a smooth and uniform finish, Abrasteel’s felt brush with keyway is the perfect tool. Specifically designed for satin finishing machines, this brush delivers a superior-quality finish on metal surfaces.

How to select the right abrasive brush

Selecting the right brush is a critical factor for success in any industrial application.

Here are some tips for choosing the ideal brush:

- Material to be worked: Identify the type of surface or material you will be working with. Each material may require a different level of abrasiveness. For example, harder metals may need a brush with more resistant bristles.

- Desired type of finish: Consider the result you want to achieve. For fine finishes, brushes with softer bristles are ideal, while harder bristles are preferred for aggressive material removal.

- Tool compatibility: Make sure the brush is compatible with the tool you plan to use, both in terms of fit and operating capacity.

Advantages of abrasive brushes

Abrasive brushes offer numerous advantages in the industrial field, including:

- Efficiency in cleaning and grinding: These brushes are capable of effectively removing rust, paint, and other residues, saving time and effort.

- Versatility: With a wide variety of brushes available, they can be used across a range of materials and applications, from fine polishing to heavy grinding.

- Precision in finishing: They provide a uniform, high-quality finish, which is crucial for many manufacturing and finishing processes.

Tips for use and maintenance

To keep abrasive brushes performing at their best, it is important to follow good use and maintenance practices:- Regular inspection: Check the brush for signs of wear or damage before each use.

- Proper use: Apply the correct pressure during use and avoid forcing the brush, as this can lead to premature wear and reduced effectiveness.

- Proper storage: Store the brushes in a dry, protected place to prevent damage from moisture or extreme temperature changes.

Abrasive brushes are essential for achieving high-quality finishes in the industry. We invite you to explore Abrasteel’s full range of abrasive brushes at www.abrasteel.com. Our team is ready to advise you and help you select the perfect brush for your needs. Together, we can achieve the best results in your industrial projects.

Contact us

Leave us your details and one of our sales representatives will contact you shortly.