Industrial abrasives

Industrial abrasives: what they are and why they are essential for your industry

Industrial abrasives are materials used to modify, cut, polish, or refine surfaces through friction. They are present in virtually all industrial processes where a part needs to be transformed or its finish improved, whether in the manufacturing of metal components, the maintenance of structures, or the restoration of surfaces.

Their main function is to remove unwanted material—such as burrs, rust, or irregularities—and prepare the surface for subsequent treatment, such as painting, welding, or coating. In addition, they are essential for ensuring the precision, safety, and durability of final products.

From large metallurgical plants to artisanal workshops, abrasives are an indispensable tool for achieving high-quality technical or aesthetic finishes. Their versatility and effectiveness make them silent protagonists across multiple industries, including automotive, construction, woodworking, and the aerospace industry.

Table of Contents

Types of industrial abrasives and their applications

Industrial abrasives can be classified according to their origin, hardness, format, and application. Understanding these differences is key to selecting the most suitable product for each task. At Abrasteel, we offer a complete range of abrasive solutions designed to cover all stages of the surface treatment process, from initial cutting to final finishing.

Rigid abrasives vs. flexible abrasives

- Rigid abrasives: These include discs, grinding wheels, and brushes designed for applications that require intensive cutting or grinding. They are ideal for removing large amounts of material quickly and precisely.

- Flexible abrasives: These include abrasive belts, rolls, and sheets that allow for more detailed and versatile work, adapting to curved or complex surfaces.

Main abrasive products distributed by Abrasteel

Abrasive discs

Discs are essential tools for cutting, grinding, and sanding operations. At Abrasteel, you will find:

- Cutting discs: Such as the XTREM INOX for stainless steel or the ALU for aluminum, they ensure clean and precise cuts.

- Grinding discs: Ideal for removing material from hard metals. Models such as GRIND POWER stand out for their durability and efficiency.

- Flap discs: They combine material removal capacity with surface finishing. The CERAMIC and TURBO INOX deliver professional results in demanding applications.

Abrasive brushes

Perfect for cleaning, stripping, and satin finishing of metals:

- Shaft-mounted brushes: Precision in hard-to-reach areas.

- Keyway-mounted brushes: For aggressive cleaning on industrial surfaces.

- Ventilated brushes: Uniform and satin finishing on large surfaces.

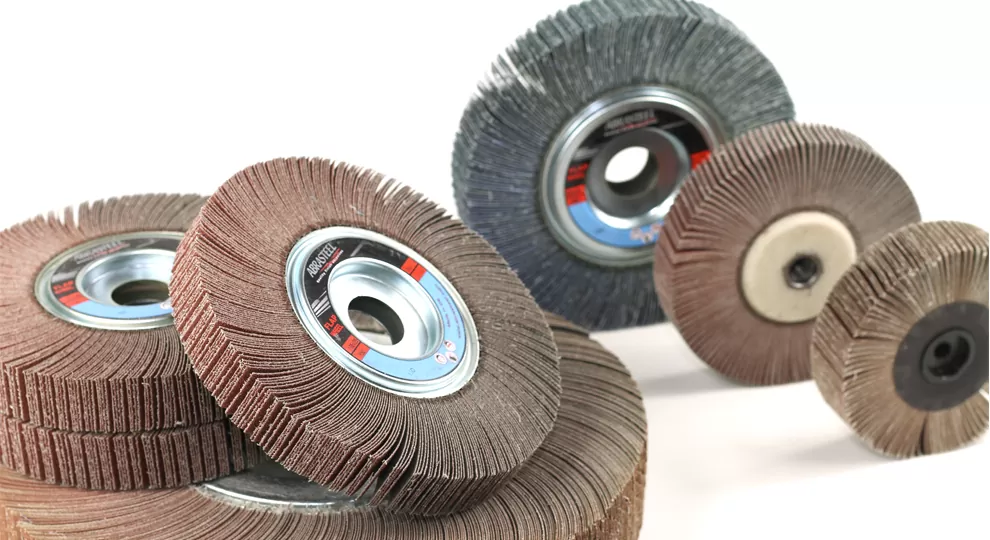

Abrasive wheels

Designed for controlled grinding and polishing:

- Compressed fiber wheels: Such as REBEL ONE, they combine abrasive action and finishing in a single tool.

- Customizable grinding wheels: Available in monocrystalline, silicon carbide, or corundum, tailored to each process.

Abrasive rolls, belts, and cloths

Flexible and versatile solutions for manual sanding or machine-assisted applications:

- Abrasive belts: Made of zirconia, ceramic, or silicon carbide, for high-demand applications.

- Abrasive rolls and cloths: Suitable for precise finishes or polishing in small areas.

Polishing compounds

They complement the abrasion process with glossy finishes and surface protection. Ideal for removing imperfections and achieving mirror effects on stainless steel, aluminum, or brass.

Factors to consider when selecting industrial abrasives

Choosing the right abrasive not only ensures optimal results but also reduces tool wear, improves process efficiency, and extends the service life of treated parts. To make the right choice, it is essential to consider several key factors:

Type of material to be worked

Not all abrasives perform the same way on different materials. For example:

- For stainless steel, ceramic or refined aluminum oxide discs are recommended.

- For aluminum, it is better to choose abrasives that do not clog, such as discs specifically designed for soft metals.

- For wood or composite materials, flexible abrasives adapt better to the shape and texture.

Desired finish

The type of abrasive directly influences the final appearance:

- For rough finishes or intensive grinding processes, a coarse grit and rigid tools such as grinding wheels or grinding discs are recommended.

- If a satin or glossy finish is desired, fine grit, polishing compounds, and precision accessories such as ventilated brushes or fine abrasive belts should be used.

Operating conditions

Speed, pressure, and cooling are critical factors. An unsuitable abrasive can wear out quickly, damage the surface, or generate excessive heat. Abrasteel provides products designed to operate safely and efficiently under different working conditions.

Compatibility with machinery

It is essential to check that the abrasive is compatible with the machine or tool in use (grinders, sanders, satin finishers, etc.). For this reason, at Abrasteel we classify our products not only by format, but also by their compatibility with professional and portable equipment.

Applications of industrial abrasives across different sectors

Industrial abrasives are a cross-cutting solution used across multiple productive sectors, where surface treatment is key to ensuring quality, strength, and aesthetics. Thanks to their versatility, the products distributed by Abrasteel adapt to specific processes in very different environments. Below, we review some of their most notable applications:

Metallurgy

Automotive

Construction

Carpentry and cabinetmaking

Aerospace and precision industry

Innovations and trends in industrial abrasives

The industrial abrasives sector is constantly evolving to meet new demands for efficiency, sustainability, and precision. At Abrasteel, we are committed to innovation and continuous improvement, offering solutions that incorporate the latest market advances.

New high-performance abrasive materials

Manufacturers have developed more efficient and longer-lasting abrasives, such as:

- Ceramic grains: Ideal for high-demand processes, they provide greater aggressiveness and extended service life.

- Microcrystalline abrasives: They wear in a controlled manner, maintaining their cutting performance for longer.

- Technical non-woven fabrics: They combine flexibility and strength for fine or intermediate finishes.

Sustainability and eco-friendly abrasives

More and more sectors are demanding environmentally friendly solutions. Abrasteel is committed to:

- Recyclable or low environmental impact abrasives.

- Reduction of energy consumption in production processes.

- Optimized formats that minimize waste and increase efficiency per processed piece.

Integration into automated processes

Industrial automation has driven the development of abrasives designed to operate in robotic lines and CNC machinery. These products make it possible to:

- Greater repeatability and precision in finishes.

- Reduction of cycle times.

- Minimization of human errors in critical processes.

Digitalization and traceability

New digital tools make it possible to monitor abrasive performance, assess service life, and better plan replacement and maintenance processes. This trend is changing the way industrial consumables are managed.

Why choose Abrasteel as your industrial abrasives supplier

In a competitive and demanding market, Abrasteel positions itself as a trusted partner for companies seeking quality, variety, and technical advice in abrasive products. Our experience, specialized catalog, and commitment to our customers make us a strategic supplier for multiple industrial sectors.

We distribute industrial abrasives for all stages of the process: cutting, grinding, cleaning, sanding, polishing, and buffing. From discs and grinding wheels to brushes, belts, compounds, and accessories, Abrasteel offers more than 10,000 references tailored to each type of job, material, and machine.

All our products meet stringent manufacturing standards, ensuring performance, durability, and safety. We work with recognized brands and test each solution to offer abrasives that truly optimize your production processes.

We have a specialized technical team that understands the challenges of each sector. We help you choose the right abrasive, improve your processes, and reduce unnecessary costs, whether you manage a large industrial plant or operate an artisanal workshop.

We continuously invest in the incorporation of new abrasive materials and technologies, so that our customers are always one step ahead in efficiency, sustainability, and precision.

Shall we talk?

Industrial abrasives are essential for transforming, preparing, and perfecting surfaces across a wide range of sectors. Choosing the right product makes a difference in productivity, quality, and operating costs. At Abrasteel, we offer you a comprehensive solution with professional products, personalized support, and deep technical expertise in the abrasives market.

Are you looking for an expert supplier of industrial abrasives?

Trust Abrasteel: the precision you need, with the range your industry demands.

Contact us

Leave us your details and one of our sales representatives will contact you shortly.