Boilermaking tools

Professional solutions for metalworking

Boilermaking is one of the most demanding branches of the metallurgical industry. It involves the transformation and assembly of sheets, profiles, and metal structures, with applications ranging from shipbuilding to the manufacture of tanks, machinery, or industrial components. To achieve high-quality results and ensure safety at every stage of the process, boilermaking workshops rely on a constant supply of specialized tools and consumables.

In this context, having reliable cutting discs, high-performance abrasives, brushes adapted for surface cleaning, and durable sanding belts becomes a strategic necessity. Choosing the right tools not only improves productivity but also ensures precise finishes and extends the lifespan of the worked pieces.

With its experience in industrial abrasives, Abrasteel offers a comprehensive catalog that meets the specific demands of boilermaking, positioning itself as a key partner for professionals in the sector.

Article content

Boilermaking tools

Boilermaking tools encompass a set of consumables, abrasives, and accessories designed to facilitate the transformation, cutting, joining, and finishing of metal, primarily iron and steel. Their function goes far beyond simple cutting operations: they allow for sheet preparation, burr removal, smoothing of weld seams, cleaning of rusted surfaces, and achieving precise finishes that meet the quality standards required in industrial sectors.

Within boilermaking, work is carried out on both light structures (doors, tanks, metal furniture) and large assemblies (heavy metalwork, shipbuilding, industrial boilers). In all cases, the operator requires tools that combine strength, durability, and safety, as the processes are often intensive and repetitive.

For this reason, boilermaking tools are not limited to cutting discs but also include grinding discs, flap discs, abrasive brushes, wheels, sanding belts, and abrasive rolls, all of which are essential to ensure that the metal is perfectly prepared at each stage of the work.

Main tools used in boilermaking

Cutting discs

Cutting discs are one of the most commonly used tools in boilermaking. They allow for precise cuts on sheets, profiles, and iron and steel pipes. In heavy boilermaking work, where thick pieces are handled, discs that combine cutting aggressiveness and thermal resistance are required, ensuring fast progress without compromising safety. Abrasteel’s TOP cutting discs, certified according to the EN12413 standard, meet these requirements and provide reliable performance for intensive cutting.

Grinding discs and flap discs

After cutting, grinding is a fundamental step in boilermaking workshops. Grinding discs remove weld seams and burrs, while flap discs allow for a finer finish, leaving the surface ready for subsequent operations such as painting or coating. Abrasteel offers both solutions, with lines that provide durability, reduced heat generation, and consistent finishes on structural steel and stainless steel.

Abrasive brushes and cleaning accessories

Metal surface preparation includes the removal of rust, old paint, and contaminants. For this purpose, abrasive brushes in different formats are used: with a core, ventilated, or with a shaft. These brushes can adapt to flat, curved, or irregular surfaces, providing deep cleaning without damaging the integrity of the metal. In boilermaking, where surface quality is critical, they are indispensable tools.

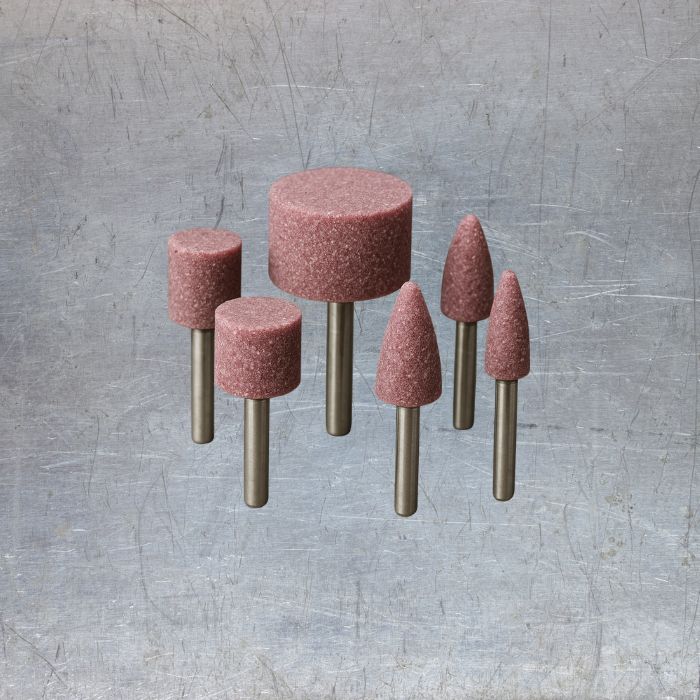

Abrasive wheels

Abrasive wheels, both flat and mounted on a shaft, are used for tool sharpening, weld finishing, and targeted grinding on hard-to-reach parts. Their versatility makes them an indispensable resource for precision work in boilermaking workshops.

Abrasive belts and rolls

When it comes to large surfaces or curved parts, abrasive belts and rolls provide an efficient solution. These tools allow for uniform sanding, with high material removal capacity and adaptability, which is crucial for large metal structures or industrial tanks.

Key Factors When Choosing Boilermaking Tools

Choosing the right tools in boilermaking depends not only on the availability of consumables but also on technical criteria that ensure consistent performance when working with iron and steel. Among the most important factors are:

Strength and durability

Abrasive tools must withstand intensive workloads without premature loss of performance. This translates into fewer consumable changes, time savings, and greater workshop profitability.

Certified safety

Using discs and wheels that comply with standards such as EN12413 or have OSA certifications ensures they have been tested under extreme conditions. For boilermaking professionals, where the risk of accidents is high, this safety is essential.

Compatibility with different types of steel

Boilermaking works with carbon steels, stainless steels, and, in some cases, special alloys. Therefore, consumables must be formulated to suit each type of material without compromising the finish.

Cost-performance ratio

The cheapest option is not always the most suitable. A higher-quality product, with longer lifespan and consistent performance, helps reduce downtime and increase overall productivity.

These factors make the difference between a workshop that operates reactively and one that achieves top-quality finishes with optimal cost control.

Abrasteel as a Supplier for Boilermaking

In the boilermaking sector, having a specialized supplier makes the difference between meeting deadlines with quality or facing delays and additional costs. Abrasteel positions itself as a strategic partner for workshops and metallurgical companies, thanks to a catalog that covers all stages of the process: from the initial sheet cutting to the final surface finishing.

Our offering includes high-performance cutting and grinding discs, designed for working with iron and structural steel, as well as flap discs and abrasive brushes that allow for cleaning, preparing, and perfecting each welded joint. Additionally, we provide wheels and abrasive belts adapted to flat and curved surfaces, offering solutions for both light and heavy boilermaking.

Beyond the product, Abrasteel provides specialized technical advice, guiding each client to the most suitable tool based on the type of material, intensity of use, and required finish. This personalized support ensures that every boilermaking workshop can optimize productivity and improve safety in its processes.

With over 25 years of experience, we operate under international quality and safety standards, allowing us to provide our clients with the assurance that every tool meets the most demanding industry requirements.

Abrasteel, Your Ally in Boilermaking Tools

Boilermaking is a sector that demands precision, strength, and a constant availability of abrasive tools for every stage of the process, from cutting to final finishing. Having certified, durable consumables adapted to different types of steel not only ensures the quality of the work but also improves productivity and reduces operational costs.

In this context, Abrasteel positions itself as a trusted supplier for boilermaking workshops and companies, offering a comprehensive catalog of cutting discs, grinding discs, flap discs, brushes, wheels, and belts. Each product has been designed to meet the real demands of the industry, with the safety and performance guarantee that only a specialist can provide.

FAQs

What are boilermaking tools?

Boilermaking tools are specialized consumables and equipment used in the transformation of sheets and metal structures, primarily iron and steel. They include cutting discs, grinding discs, wheels, abrasive brushes, and sanding belts. These tools enable cutting, preparing, welding, and finishing metal surfaces, ensuring that the final products meet high standards of precision and durability.

What types of tools are used in boilermaking?

In a boilermaking workshop, the main tools used are cutting discs for iron and steel, which allow clean and fast cuts; grinding and flap discs, which remove weld seams and burrs; abrasive brushes, which clean and prepare surfaces by removing rust and paint; and wheels or abrasive belts, ideal for sharpening and sanding large pieces. Each tool serves a specific function within the manufacturing and finishing process.

Why is quality important in boilermaking tools?

The quality of boilermaking tools directly affects productivity, safety, and the final finish of worked pieces. A low-quality cutting disc can break easily, compromising operator safety, while a poorly resistant abrasive requires frequent replacements, increasing costs and reducing efficiency. Tools certified under standards such as EN12413 or approved by OSA ensure they can withstand the demands of metalworking without compromising performance.

What materials are commonly worked on in boilermaking?

Boilermaking workshops primarily work with carbon steel, stainless steel, and iron, although special alloys are also used in certain projects. Each material behaves differently during cutting and grinding, making it essential to choose the appropriate abrasive tool to ensure precision, durability, and a professional finish.

Where to buy professional-quality boilermaking tools?

Boilermaking tools should always be purchased from suppliers specialized in industrial abrasives, capable of guaranteeing quality, availability, and technical advice. Abrasteel offers a comprehensive catalog of cutting discs, grinding discs, flap discs, brushes, wheels, and belts, all designed to meet the demands of boilermaking workshops. Additionally, it provides technical support to select the most suitable abrasive for each application.

Contact us

Leave us your details and one of our sales representatives will contact you shortly.