A bit of science: Abrasive cutting

Why can a cutting disc cut steel while scissors cannot?

At first glance, it may seem that cutting a metal is simply a matter of force or sharpness. However, when we try to cut a steel bar with household scissors (or even industrial ones), the result is frustrating: nothing happens. In contrast, a thin cutting disc, spinning at high speed, can slice through that same steel with surprising ease. Why?

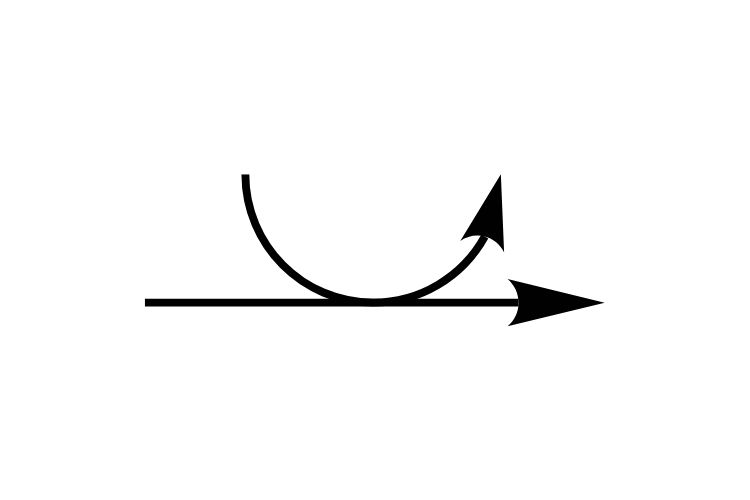

The difference lies in the nature of the cut and the energy involved. Scissors exert pressure on a specific area of the material, hoping it will yield mechanically. But steel does not give in so easily: it is hard, tough, and resistant to deformation. Unlike softer materials like paper, metal requires much more than pressure: it needs abrasion and high-speed friction.

A cutting disc does not cut like a blade would; instead, it wears away the material at a microscopic level thanks to its surface loaded with extremely hard abrasive grains (usually aluminum oxide, zirconia, or ceramic). These grains act like thousands of tiny irregular blades that, when spinning at speeds of up to 13,000 rpm, remove particles from the metal through impact, friction, and localized heat.

Moreover, during abrasive cutting, a high temperature is generated at the point of contact. This momentarily reduces the hardness of the metal, making it easier to cut without compromising the integrity of the piece. That combination of abrasive hardness + kinetic energy + heat is what makes the cutting disc such an effective tool for working with metals.

Thus, rather than a clean cut like that of a saw, the disc performs extreme and controlled material removal, capable of penetrating even stainless steels or metal structures with great precision and speed.

How Abrasive Cutting Works: A Scientific Perspective

Unlike traditional mechanical cutting—such as with shears, a handsaw, or even a blade—abrasive cutting is based on physicochemical principles involving friction, controlled erosion, and heat transfer. There is no defined edge that separates the material; instead, a rough and extremely hard surface wears down the piece through a microfracture process.

The Abrasive Grain and Its Hardness

The key lies in the abrasive grain of the disc. These grains are usually made of materials such as aluminum oxide, zirconia, or ceramic (ceramic aluminum oxide). All of them far exceed the hardness of stainless steel, iron, or aluminum, allowing them to fracture the metal at a microscopic scale upon contact, releasing particles or shavings.

These grains are fixed in a resin or binder matrix (usually fiberglass-reinforced phenolic resin) and are arranged to maximize cutting aggressiveness. Each particle acts like a small “sharp stone” that, thanks to the tangential speed, repeatedly impacts the metal surface.

Peripheral Speed and Kinetic Energy

For the process to be effective, the discs must reach peripheral speeds of up to 80 m/s, which equates to 13,000 revolutions per minute for 115 mm discs. This speed generates enormous kinetic energy, capable of overcoming the metal’s resistance and enabling continuous material removal.

This energy, when concentrated on such a small point of contact, also generates a high temperature. This heat has a dual effect: it slightly softens the material being worked and helps the disc maintain its cutting ability by removing metal residues adhered to the abrasive grain (self-cleaning effect through friction).

The Result: Clean, Precise, and Deformation-Free Cutting

Despite the name, cutting discs do not deform the material being worked like a blade or a press might. The process is so fast and localized that excessive heat transfer to the rest of the piece is avoided, minimizing the risk of internal stresses or shape alterations. For this reason, abrasive cutting is ideal for:

- Pipes and Metal Profiles

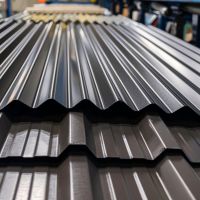

- Thick or Thin Sheets

- Delicate Materials Such as Stainless Steel

- Structural Elements

This precision, combined with the speed of the cut, makes the abrasive disc an indispensable tool in sectors such as boiler making, welding, industrial assembly, and metal structures.

Factors Affecting the Effectiveness of Cutting with Abrasive Discs

Although the principle of abrasive cutting may seem simple—hard grains rotating at high speed against metal—the actual performance of the process is influenced by multiple factors. Knowing them is key to optimizing the work, preventing premature disc wear, and improving the quality of the final cut.

Type of Abrasive Grain

The grain material determines the disc’s aggressiveness and durability:

Aluminum Oxide

Standard and economical, suitable for carbon steel and cast iron.

Zirconia

Higher performance in intensive grinding and demanding cuts, with good thermal resistance.

Ceramic

Maximum performance, lower wear, ideal for stainless steel and high-alloy materials.

The choice of grain directly affects the disc’s lifespan, cutting speed, and finish quality.

Hardness and Structure of the Material to Be Cut

Not all metals behave the same way. A disc that performs excellently on structural steel may not be the most suitable for aluminum or stainless steel. The material’s density, elasticity, and thermal conductivity influence:

Ease of Chip Removal

Dissipation of Generated Heat

Adhesion of Metal Particles to the Disc

For this reason, it is crucial to choose a disc compatible with the specific material of the workpiece.

Cutting Speed and Applied Pressure

The disc speed must be adjusted according to its diameter and the manufacturer’s specifications. Insufficient speed will not cut properly, while excessive speed can generate heat, disc fatigue, or even breakage.

Additionally, the applied pressure must be firm but controlled. If pressed too hard, wear accelerates without gaining performance. If pressed too lightly, the disc will not penetrate the material. Ideally, the abrasive should do the work with a steady, moderate pressure.

Cooling and Heat Control

Although abrasive cutting is dry, in critical industrial processes (such as cutting pipes or batch parts), liquid cooling or compressed air can be applied to reduce overheating. This prevents:

Ease of Chip Removal

Brittleness at the Edges

Deformations or Discoloration in Stainless Steels

Disc Quality and Certifications

Not all abrasive discs have the same level of safety and reliability. At Abrasteel, all our cutting discs are manufactured according to the EN12413 standard, and many are OSA certified, which ensures:

- Quality Control of Materials

- High-Speed Safety

- Consistent Performance Across the Entire Production Batch

Using certified discs not only improves performance but also protects the operator and the machinery.

Industrial Applications of Abrasive Cutting with Discs

Abrasive cutting with discs is not just a workshop technique: it is a key component in numerous industrial sectors. Its effectiveness, versatility, and adaptability to different materials have made it an indispensable tool for both mass production and maintenance and repair work.

Metal Construction and Structures

In the fabrication of metal structures—from industrial buildings to bridges or platforms—cutting discs allow:

- Cutting profiles, beams, sheets, or flat bars of carbon and stainless steel

- Preparing Joints for Welding (Chamfers, Square Cuts)

- Adapting Components on Site Quickly and Precisely

Thanks to their portability, operators can cut on-site without the need for heavy machinery.

Boilermaking and Tank Fabrication

In boilermaking work, where thick sheets and large-diameter metal pipes need to be cut, cutting discs provide a reliable, fast, and cost-effective solution. They are used in both manual processes and automated stations for repetitive cutting.

Additionally, in tanks for liquids or pressurized gases, cutting precision prevents edge deformations that could compromise welding.

Shipyards and Naval Maintenance

The marine environment presents unique challenges: thick, tough, and often corroded materials. In this context, cutting discs allow:

- Removing Defective Sections of Hull or Structure

- Cutting Tubular Elements or Naval Steel Plates

- Working in Adverse Conditions Where Other Technologies Cannot Be Used

Operating in Adverse Conditions Where Other Technologies Cannot Be Used

Railway Sector

From cutting tracks to adapting metal parts in rolling stock, the abrasive disc remains the most efficient solution in the field. Some discs are specifically designed to cut rails with high precision, such as the rail-cutting discs in Abrasteel’s catalog.

Industrial Maintenance

In factories, power plants, and production lines, corrective and preventive maintenance often requires cutting worn metal parts, damaged profiles, or clogged pipes. Abrasive cutting, being portable and fast, allows immediate interventions without the need to disassemble machinery.

Advantages of Disc Cutting Compared to Other Techniques

Metal cutting can be performed using various technologies: plasma, laser, oxy-fuel cutting, or mechanical shearing, among others. However, abrasive disc cutting offers a range of practical and technical advantages that make it a preferred solution in many situations.

Versatility in Materials and Shapes

Cutting discs allow work not only with carbon steel, stainless steel, or cast iron, but also with non-ferrous materials such as aluminum, bronze, or copper. Additionally, they can cut pipes, profiles, sheets, or irregular parts, even in complex positions.

Speed of Intervention

Unlike laser or water jet cutting machines, discs do not require programming or extensive setup. An operator can act quickly, even in confined spaces or maintenance tasks.

Reduced Cost

The initial and operating cost of an abrasive disc is much lower than that of other industrial cutting methods. It does not require gases, cooling liquids, or complex electronic systems, which reduces overall production or repair costs.

Portability and Autonomy

The initial and operating cost of an abrasive disc is far lower than that of other industrial cutting methods. It does not require gases, cooling liquids, or complex electronic systems, which reduces overall production or repair costs.

Acceptable Precision and Good Finish

Although it does not achieve the detail of laser cutting, the abrasive disc can provide clean and controlled cuts, especially with high-quality discs like those in Abrasteel’s catalog. The choice of disc type, grit, and thickness directly affects cutting precision.

Abrasive Disc Cutting: Efficiency, Precision, and Cost-Effectiveness for Metal Professionals

Abrasive disc cutting is not just a technique; it is a complete solution that combines operational simplicity with high efficiency. Thanks to the speed of the process, ease of use, and the wide variety of available discs, it has become an indispensable option in sectors such as boilermaking, automotive, metal construction, and industrial maintenance.

At Abrasteel, we offer professionals a catalog of cutting discs designed to meet any need: from fast, aggressive cuts to finer finishes, on ferrous metals or special alloys.

Do you want to optimize your cutting processes without compromising quality or your budget?

Discover our certified cutting discs and achieve professional results with every application.

FAQs

What is a grinding disc and how does it differ from a cutting disc?

A grinding disc is an abrasive tool designed to remove material from the surface of a workpiece, usually metal, through friction. It is mainly used to reduce weld beads, remove imperfections, or level metal structures. Although at first glance it may look similar to a cutting disc, its construction is different: grinding discs are thicker, more robust, and designed to work with the side of the disc, not the edge. In contrast, cutting discs are thin and specifically designed to penetrate materials, separating them completely through direct abrasion. Both are part of the abrasive cutting process with discs, but with very different functions.

Why is it important to grind a weld?

Grinding a weld is an essential part of any metal manufacturing or repair process, as it improves both the strength and aesthetics of the assembly. Welded joints often leave a bead that, in addition to protruding from the original plane, may contain small imperfections or unfused areas that weaken the structure. By grinding correctly, these irregularities are eliminated, the transition between parts is smoothed, and a surface suitable for painting, coating, or inspection is achieved. Furthermore, in sectors where high precision and strength are required, such as automotive or boiler making, grinding is essential to ensure the reliability of the assembly.

What materials can be cut with abrasive discs?

Abrasive cutting discs are designed to work on a wide variety of materials, although their main use is focused on metals. Carbon steel, stainless steel, cast iron, aluminum, or special alloys can be cut effectively using the right type of disc. The key is to choose the right abrasive grain: aluminum oxide discs are ideal for mild steels, while zirconium or ceramic discs offer superior performance on hard steels or heat-treated materials. There are also specific discs for other materials such as stone or reinforced plastics, although their application is less common in metal-focused industrial environments.

How can you tell if a cutting disc is worn out?

Wear and tear on an abrasive cutting disc is inevitable with use, but there are clear signs that indicate when it is time to replace it. If the disc has lost a significant amount of diameter, vibrates abnormally during cutting, or shows irregularities on the edge (such as cracks, burns, or loss of material), it is best to replace it. Similarly, if the cutting speed decreases or more pressure is required to complete the task, this may be a sign of worn abrasive. Working with discs in poor condition not only compromises the quality of the work, but also the safety of the operator.

What type of disc is recommended for cutting stainless steel?

To cut stainless steel efficiently and safely, it is recommended to use abrasive discs made of zirconium or ceramic grain, as these materials maintain their cutting capacity even on hard and heat-resistant surfaces. Unlike common aluminum oxide discs, zirconium discs offer a longer service life and a cleaner cut on stainless steel, without burning or deforming the material. It is also essential that the disc be free of iron, sulfur, or chlorine to avoid contamination that could affect the passivation of the steel. Brands such as Abrasteel offer specific models designed for these types of demanding applications.

Contact us

Leave us your details and one of our sales representatives will contact you shortly.